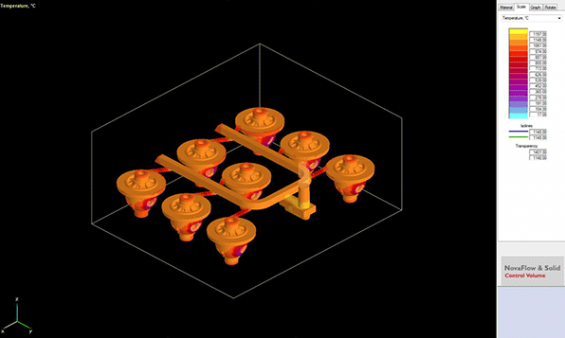

Production preparation

for the best quality of castings

Preparing a new casting for production, we rely not only on our many years of foundry experience, but also on the most modern tools supporting engineering work.

For the design process, we use the Siemens NX CAD / CAM software, in which we create 3D models and flat documentation of model plates and castings.

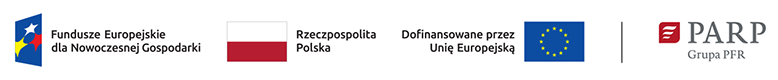

SIMULATION OF POURING AND SOLIDIFICATION

Production quality control at every stage

COOPERATION FOR INNOVATION

cooperation with AGH and the Foundry Institute

SMALL RUNS AND ONE OFF CASTS

castings for individual orders

Smaller series and castings with dimensions or

weights exceeding the capabilities of our molding lines, we make on the manual

molding plant.